Nuclear energy has been under much controversy, but most of it is based on myths. These nuclear energy facts will tell you everything you need to know about this alternative energy source.

- Over 450 nuclear power reactors are used around the world.

- About 31 different countries have operational nuclear reactors.

- Nuclear energy supplies 11% of the world’s electricity.

- It is the second-highest provider of low-carbon energy in the U.S., next to hydro energy.

- Nuclear power plants are safer work environments compared to offices.

- Enrico Fermi is the father of nuclear energy. He discovered nuclear fission and created the first nuclear power plant, the Chicago Pile-1.

- The word ‘nuclear’ stems from the nucleus of an atom.

- Nuclear energy is released from “nuclear fission” or the process of splitting an atom in two.

- The first commercial nuclear power stations started operating in the 1950s.

- There have been over 55 tests a year for the last 30 years.

- Uranium is the most common fuel for nuclear energy.

- The U.S., France, and Japan are the largest producers of nuclear power.

- Nuclear waste is radioactive and must be disposed of properly.

- In the history of nuclear energy, there have been 3 major disasters – Three Mile Island, Fukushima, and Chernobyl.

- Only 2 nuclear weapons have ever been used in warfare, although many weapons have been tested.

- A rem is a large dose of radiation.

- Every creature on Earth receives an average of 300 – 500 mrem (milirems) a year.

- France uses 80% nuclear energy as an electricity source.

- Nuclear fusion is the safest way to create power.

- Uranium was also used to color stained glass in the medieval ages.

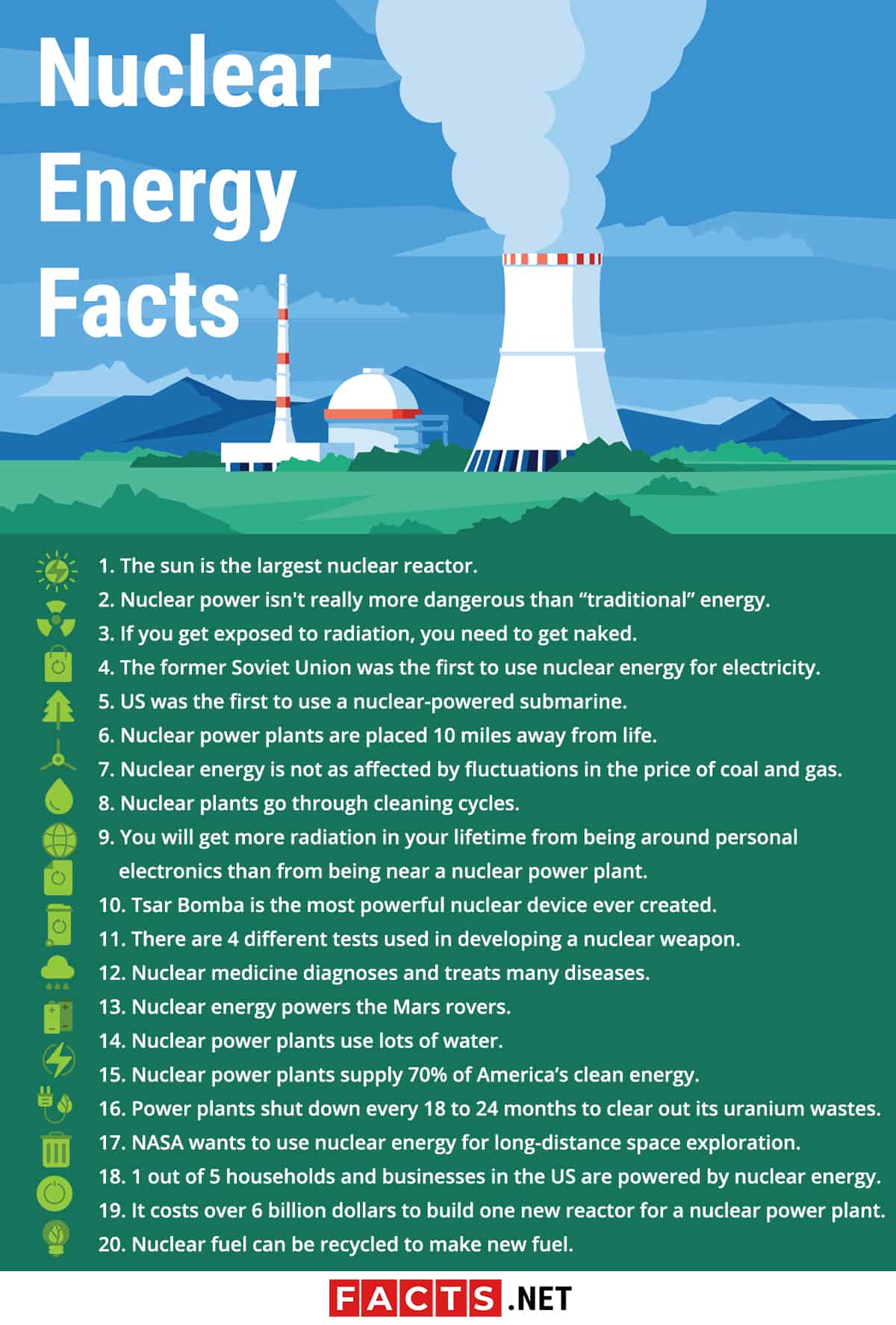

Nuclear Energy Facts Infographics

The sun is the largest nuclear reactor.

The sun converts hydrogen into helium through nuclear reactions. Through nuclear fusion, the Sun fuses 620 million metric tons of hydrogen and makes 606 million metric tons of helium each second in its core. This is similar to how nuclear reactors produce heat, and consequently, energy. The heat created by nuclear fission makes steam that spins a turbine to generate electricity.

Nuclear power isn't really more dangerous than “traditional” energy.

Over 10 major disasters have been caused by fossil fuel energy in the last 25 years – namely, the BP oil spill. On the other hand, only three have been caused by nuclear power.

If you get exposed to radiation, you need to get naked.

One of the weirder yet essential nuclear energy facts: If you get exposed to nuclear substances, the best course of action is to remove all of your clothes. This will remove 90% of the radioactive substance you were exposed to.

The former Soviet Union was the first to use nuclear energy for electricity.

The Obninsk Power Plant began operating in 1954. Being the first nuclear power plant to produce industrial electricity, it operated successfully for nearly 5 decades before shutting down in 2002.

US was the first to use a nuclear-powered submarine.

The USS Nautilus was the first submerged vessel to go under the North Pole. It launched in 1954 and served until 1980.

Nuclear power plants are placed 10 miles away from life.

As a safety measure, nuclear power plants are built generally far from communities.

Nuclear energy is not as affected by fluctuations in the price of coal and gas.

Unlike other energy sources, nuclear power is somewhat independent in terms of economic value, since it does not rely on external resources such as coal or gas. These resources are prone to price fluctuation, but nuclear energy is mostly safe from that.

Nuclear plants go through cleaning cycles.

For every 1.5 – 2 years, nuclear plants shut down to allow radioactive waste removal.

You will get more radiation in your lifetime from being around personal electronics than from being near a nuclear power plant.

Despite concerns about radiation exposure, research shows that long-term exposure to certain electronics would have more radiation than proximity to power plants.

Tsar Bomba is the most powerful nuclear device ever created.

The Tsar Bomba of the former Soviet Union was tested in 1961 over Novaya Zemlya. It produced a mushroom cloud that could be seen from over 600 miles away.

There are 4 different tests used in developing a nuclear weapon.

Nuclear weapons undergo atmospheric, underwater, exoatmospheric, and underground tests before being cleared for use.

Nuclear medicine diagnoses and treats many diseases.

Nuclear power creates isotopes used for examining the body. A more common product of nuclear energy in medicine is radiotherapy which targets and destroys cancer cells.

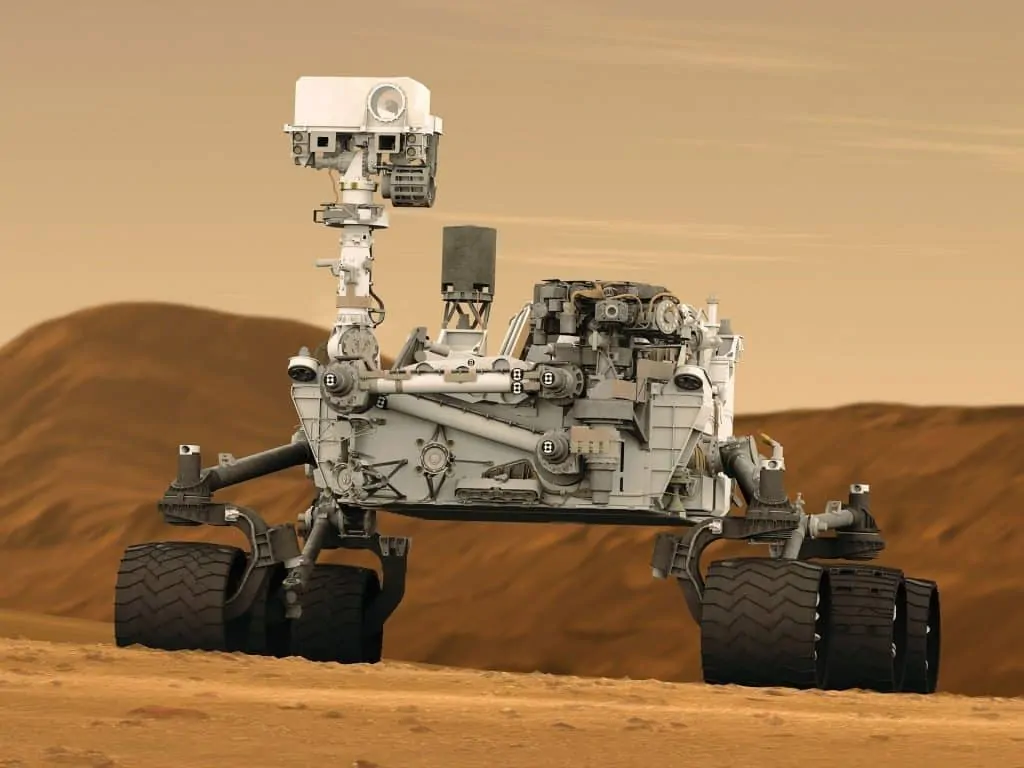

Nuclear energy powers the Mars rovers.

Prior Mars expeditions relied on solar panels, but the exploration process was slowed down by dust build-up on the solar panels or days with little sunlight. To solve this, NASA devised the Multi-Mission Radioisotope Thermoelectric Generator (MMRTP). The MMRTP is an energy source that relies on the heat generated by decaying plutonium dioxide to power the Curiosity rover.

Nuclear power plants use lots of water.

Nuclear plants use large amounts of water for steam production and cooling.

Nuclear power plants supply 70% of America’s clean energy.

One of the benefits of nuclear energy: Because nuclear waste is recyclable, nuclear energy is seen as a “clean” and sustainable energy.

Power plants shut down every 18 to 24 months to clear out its uranium wastes.

These wastes are then processed or recycled, or stored in cooling lakes.

NASA wants to use nuclear energy for long-distance space exploration.

One of the nuclear energy facts to look forward to: NASA’s Project Prometheus is NASA’s initiative to use nuclear power for space exploration. The use of nuclear power could increase exploration speeds and cut down the costs of missions.

1 out of 5 households and businesses in the US are powered by nuclear energy.

The U.S. is responsible for over 30% of the world’s nuclear energy.

It costs over 6 billion dollars to build one new reactor for a nuclear power plant.

Nuclear power plants may be expensive to build, but they are relatively cheap to run. Nuclear energy competes with fossil fuels as a means of electricity generation. If you consider the environmental and economic consequences of long-term reliance on fossil fuels, nuclear energy shines as an alternative energy source.

Nuclear fuel can be recycled to make new fuel.

Nuclear energy recycling is a process that takes time. Most of the waste from this process will require a storage time of less than 300 years. Less than 1% is radioactive for 10,000 years. By this point, the radiation is so minimal that it is almost the same as natural radiation found in soil or other surroundings, and can easily be shielded to protect life.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.